Dynamic Controls Power chair, RC Boat trailer project

Re: Dynamic Controls Power chair, RC Boat trailer project

New controller is working nearly exactly as old.

Old i ran at full power all the time , new i need to run 1 step back from full.

Same settings but full power on the new controller/power module is equal to one less on the rabbit/tortoise speed meter on the joystick.

ie, old controller ran at ' 6 ', new performs identical at ' 5 ' .

New one is a tiny bit faster on the Q6 Edge base its fitted to.

Old i ran at full power all the time , new i need to run 1 step back from full.

Same settings but full power on the new controller/power module is equal to one less on the rabbit/tortoise speed meter on the joystick.

ie, old controller ran at ' 6 ', new performs identical at ' 5 ' .

New one is a tiny bit faster on the Q6 Edge base its fitted to.

http://greenmobility.com.au/rc-wheelchair-controller/

My YouTube Ch -- https://www.youtube.com/user/gcebiker

My YouTube Ch -- https://www.youtube.com/user/gcebiker

-

gcebiker - Posts: 879

- Joined: 11 Jul 2015, 14:20

- Location: Gold Coast, Queensland, Australia.

Re: Dynamic Controls Power chair, RC Boat trailer project

And on a completely different tangent....

The stock controller for the Q6 Edge...DISCHARGES THE BATTERIES>>...

yes, it charges ...then discharges the batteries.

Years ago i went to an after market 24v "scooter charger" and my batteries have lasted me 11 Years !

I tried using the stock charger for the last 2 weeks and every day it went flat ...like half an hour after taking it off charge !

SO went back to the ebay 24v scooter charger and ............its been TWO solid days of use around the house (the only place i use the house chair) and its still at full LED charge (i have not put in the meter to check its physical voltage).

Is Pride Mobility knowingly selling 'Dumb' Chargers that don't AUTO Float ?

Cant be an accident, the charger i was using is brand new.

Perhaps instead of putting LiPo in our chairs we should first look at the chargers the manufacturers put with them.

Knowingly selling chargers that dont block the discharge after they are full is a REALLY BIG FAIL, if not criminal !

The stock controller for the Q6 Edge...DISCHARGES THE BATTERIES>>...

yes, it charges ...then discharges the batteries.

Years ago i went to an after market 24v "scooter charger" and my batteries have lasted me 11 Years !

I tried using the stock charger for the last 2 weeks and every day it went flat ...like half an hour after taking it off charge !

SO went back to the ebay 24v scooter charger and ............its been TWO solid days of use around the house (the only place i use the house chair) and its still at full LED charge (i have not put in the meter to check its physical voltage).

Is Pride Mobility knowingly selling 'Dumb' Chargers that don't AUTO Float ?

Cant be an accident, the charger i was using is brand new.

Perhaps instead of putting LiPo in our chairs we should first look at the chargers the manufacturers put with them.

Knowingly selling chargers that dont block the discharge after they are full is a REALLY BIG FAIL, if not criminal !

http://greenmobility.com.au/rc-wheelchair-controller/

My YouTube Ch -- https://www.youtube.com/user/gcebiker

My YouTube Ch -- https://www.youtube.com/user/gcebiker

-

gcebiker - Posts: 879

- Joined: 11 Jul 2015, 14:20

- Location: Gold Coast, Queensland, Australia.

Re: Dynamic Controls Power chair, RC Boat trailer project

All powerchair chargers are crap. I have been telling people this for years. But I don't get what you mean by discharge. If you were to discharge a pair of 70Ah batteries via a charger in an hour it would require a heat sink capable of dumping about 1200 to 1500 watts! And way thicker cable than used on a charger or wiring loom.

Your scooter charger is also crap...

http://www.wheelchairdriver.com/MK1.pdf CORRECT way to charge a gel battery.

http://www.wheelchairdriver.com/MK2.pdf AGM and GEL differences. And charging differences.

http://www.wheelchairdriver.com/MK3.pdf GEL

http://www.wheelchairdriver.com/MK4.pdf Sell sheet

http://www.wheelchairdriver.com/odyssey.pdf Better batteries...

Your scooter charger is also crap...

http://www.wheelchairdriver.com/MK1.pdf CORRECT way to charge a gel battery.

http://www.wheelchairdriver.com/MK2.pdf AGM and GEL differences. And charging differences.

http://www.wheelchairdriver.com/MK3.pdf GEL

http://www.wheelchairdriver.com/MK4.pdf Sell sheet

http://www.wheelchairdriver.com/odyssey.pdf Better batteries...

-

Burgerman - Site Admin

- Posts: 70264

- Joined: 27 May 2008, 21:24

- Location: United Kingdom

Re: Dynamic Controls Power chair, RC Boat trailer project

Aye, its shite. My chairs not charged in the morning with a stock charger.

There's not be more I know, tilli open it up on the weekend and see what's inside.

Poor form if Pride are selling DUMB chargers to folks that need reliability.

There's not be more I know, tilli open it up on the weekend and see what's inside.

Poor form if Pride are selling DUMB chargers to folks that need reliability.

http://greenmobility.com.au/rc-wheelchair-controller/

My YouTube Ch -- https://www.youtube.com/user/gcebiker

My YouTube Ch -- https://www.youtube.com/user/gcebiker

-

gcebiker - Posts: 879

- Joined: 11 Jul 2015, 14:20

- Location: Gold Coast, Queensland, Australia.

Re: Dynamic Controls Power chair, RC Boat trailer project

You do realise that no charger can charge in an 8 hour overnight cycle to 100 percent?

And that incomplete charge is what causes sulfation that sends the battery to the rubbish bin?

Takes 12 to 16 hours to fully charge.

And that incomplete charge is what causes sulfation that sends the battery to the rubbish bin?

Takes 12 to 16 hours to fully charge.

-

Burgerman - Site Admin

- Posts: 70264

- Joined: 27 May 2008, 21:24

- Location: United Kingdom

Re: Dynamic Controls Power chair, RC Boat trailer project

The stock Pride Mobility supplied charger has its indicator LED going green, battery indicator on the chair reads full...but in under an hour its dropped one green led on the Joystick and by lunch time I am into the Yellow with all green gone out.

V's the scooter charger, tops the battery up full...its 10pm and the battery indicator on the joystick is still showing full...and its driving like its got a full charge.

Just an observation for people finding the range on their chairs is not what it should be.

Look at what the charger is doing , it may also be faulty and discharging your batteries after it has finished charging overnight.

I only use this power chair around the house so its never ever run below 90%

Stock Pride charger had me thinking i needed to fit the new batteries, i went back to the ebay scooter charger and the batteries are back to lasting me 2 days before i have 2 greens down on the battery indicator.

V's the scooter charger, tops the battery up full...its 10pm and the battery indicator on the joystick is still showing full...and its driving like its got a full charge.

Just an observation for people finding the range on their chairs is not what it should be.

Look at what the charger is doing , it may also be faulty and discharging your batteries after it has finished charging overnight.

I only use this power chair around the house so its never ever run below 90%

Stock Pride charger had me thinking i needed to fit the new batteries, i went back to the ebay scooter charger and the batteries are back to lasting me 2 days before i have 2 greens down on the battery indicator.

http://greenmobility.com.au/rc-wheelchair-controller/

My YouTube Ch -- https://www.youtube.com/user/gcebiker

My YouTube Ch -- https://www.youtube.com/user/gcebiker

-

gcebiker - Posts: 879

- Joined: 11 Jul 2015, 14:20

- Location: Gold Coast, Queensland, Australia.

Re: Dynamic Controls Power chair, RC Boat trailer project

Just an observation for people finding the range on their chairs is not what it should be.

Look at what the charger is doing , it may also be faulty and discharging your batteries after it has finished charging overnight.

Stock chargers almost always give a green after about an hour in that situation. Incorrectly. They end far too soon. But some continue regardless of green, at CV voltage, some dont. Some go to a lower float voltage which continues the charge at a safer (no thermal runaway) level. What the green doesn't tell you is that its done...

A lead battery that is only 10% discharged STILL takes a full 8 hours to FULLY charge. It doesn't work like a fuel tank. The last 10% of charge is an ever decreasing current. It gets slower and slower. Until it falls to almost zero, just a few mA, its not charged FULL. That matters because it leaves lead sulfate coating the plates. This hardens, and turns to larger non conducting crystals over time. So you eventually cannot ever remove it by charging and you are screwed. Your scooter charger likely charged longer, removed at least some of the sulfates that the pride charger left. Hence better performance.

But no charger I know of can discharge a set of batteries in error unless designed to do so. Thats a lot of energy to lose.

-

Burgerman - Site Admin

- Posts: 70264

- Joined: 27 May 2008, 21:24

- Location: United Kingdom

Re: Dynamic Controls Power chair, RC Boat trailer project

But no charger I know of can discharge a set of batteries in error unless designed to do so. Thats a lot of energy to lose.

Ive the parts to build a dedicated 'inline' XLR Voltage/Current Meter.

When i have it knocked up ill do some live testing to see what is going on.

At the very least its a dumb charger and not monitoring its state of charge once it hits 'green' , Ill be able to measure and see what green means for this charger.

Ive 5 different 24v Lead acid and a few 24v LiFePo4 chargers, ill test all of them i think.

http://greenmobility.com.au/rc-wheelchair-controller/

My YouTube Ch -- https://www.youtube.com/user/gcebiker

My YouTube Ch -- https://www.youtube.com/user/gcebiker

-

gcebiker - Posts: 879

- Joined: 11 Jul 2015, 14:20

- Location: Gold Coast, Queensland, Australia.

Re: Dynamic Controls Power chair, RC Boat trailer project

Tweaked the new joystick today, the DK=REMD21.

Slightly higher top speed, the motors were only 'seeing' less than battery volts.

Fitted LED lights to the chair...slight hickup, when the lights are "off" its still delivering 16v out of the DCI 12pin port

This is the lights OFF...

This is them ON...

Somethings not quite right, i added a switch to completely turn them off .... which pretty much defeats the purpose of having a switch built into the joystick in the first place....

The lights off with manual switch fitted.

Best thing i can think of at the moment is to stick a 24v to 12v DC/DC converter in and see if the LVC works to turn them off fully.

Its an ebay special, i dont know what the value for the LVC is but ill just plug it in an see if it works.

Or it might be something in the settings, ill read over the instruction manual and see if i can find something.

Only setting i remember at the moment is the ones for the Linear Actuators Volts/Amps/timeout etc

Slightly higher top speed, the motors were only 'seeing' less than battery volts.

Fitted LED lights to the chair...slight hickup, when the lights are "off" its still delivering 16v out of the DCI 12pin port

This is the lights OFF...

This is them ON...

Somethings not quite right, i added a switch to completely turn them off .... which pretty much defeats the purpose of having a switch built into the joystick in the first place....

The lights off with manual switch fitted.

Best thing i can think of at the moment is to stick a 24v to 12v DC/DC converter in and see if the LVC works to turn them off fully.

Its an ebay special, i dont know what the value for the LVC is but ill just plug it in an see if it works.

Or it might be something in the settings, ill read over the instruction manual and see if i can find something.

Only setting i remember at the moment is the ones for the Linear Actuators Volts/Amps/timeout etc

http://greenmobility.com.au/rc-wheelchair-controller/

My YouTube Ch -- https://www.youtube.com/user/gcebiker

My YouTube Ch -- https://www.youtube.com/user/gcebiker

-

gcebiker - Posts: 879

- Joined: 11 Jul 2015, 14:20

- Location: Gold Coast, Queensland, Australia.

Re: Dynamic Controls Power chair, RC Boat trailer project

DC to DC converter sorted it out, now turns On and COMPLETELY Off via the joystick button.

Leds now running on 12v's

Converter used was one of these, waterproof i was able to stuff it in with the rest of the Power module wiring.

http://www.ebay.com.au/itm/Waterproof-D ... Swwo1Xebbw

Leds now running on 12v's

Converter used was one of these, waterproof i was able to stuff it in with the rest of the Power module wiring.

http://www.ebay.com.au/itm/Waterproof-D ... Swwo1Xebbw

http://greenmobility.com.au/rc-wheelchair-controller/

My YouTube Ch -- https://www.youtube.com/user/gcebiker

My YouTube Ch -- https://www.youtube.com/user/gcebiker

-

gcebiker - Posts: 879

- Joined: 11 Jul 2015, 14:20

- Location: Gold Coast, Queensland, Australia.

Re: Dynamic Controls Power chair, RC Boat trailer project

Bought another boat, this one is lighter than the first.

...much lighter. Should be able to launch at the Kayak ramp with the RC Power chair.

Also purchased a 95lb thrust Brushless Trolling Motor a few weeks ago.

I will see how it goes on electric only.

May end up with a full solar boat/powerchair combo.

...much lighter. Should be able to launch at the Kayak ramp with the RC Power chair.

Also purchased a 95lb thrust Brushless Trolling Motor a few weeks ago.

I will see how it goes on electric only.

May end up with a full solar boat/powerchair combo.

http://greenmobility.com.au/rc-wheelchair-controller/

My YouTube Ch -- https://www.youtube.com/user/gcebiker

My YouTube Ch -- https://www.youtube.com/user/gcebiker

-

gcebiker - Posts: 879

- Joined: 11 Jul 2015, 14:20

- Location: Gold Coast, Queensland, Australia.

Re: Dynamic Controls Power chair, RC Boat trailer project

Anyone got a second hand - battery connector / loom - they can sell me ? GSM80208

Hoping someone in Australia might have one floating about they can post.

Hoping someone in Australia might have one floating about they can post.

http://greenmobility.com.au/rc-wheelchair-controller/

My YouTube Ch -- https://www.youtube.com/user/gcebiker

My YouTube Ch -- https://www.youtube.com/user/gcebiker

-

gcebiker - Posts: 879

- Joined: 11 Jul 2015, 14:20

- Location: Gold Coast, Queensland, Australia.

Re: Dynamic Controls Power chair, RC Boat trailer project

Had a look through some old emails.

A factory plug is only $12 (in the old catalog i have) so trying to see if i can buy a new plug.

Prices will probably have gone up, since i got the catalog in 2006...

A factory plug is only $12 (in the old catalog i have) so trying to see if i can buy a new plug.

Prices will probably have gone up, since i got the catalog in 2006...

http://greenmobility.com.au/rc-wheelchair-controller/

My YouTube Ch -- https://www.youtube.com/user/gcebiker

My YouTube Ch -- https://www.youtube.com/user/gcebiker

-

gcebiker - Posts: 879

- Joined: 11 Jul 2015, 14:20

- Location: Gold Coast, Queensland, Australia.

Re: Dynamic Controls Power chair, RC Boat trailer project

Aussie agent for DX has been able to supply a DX2 Battery/motor kit so the project is back on track.

http://greenmobility.com.au/rc-wheelchair-controller/

My YouTube Ch -- https://www.youtube.com/user/gcebiker

My YouTube Ch -- https://www.youtube.com/user/gcebiker

-

gcebiker - Posts: 879

- Joined: 11 Jul 2015, 14:20

- Location: Gold Coast, Queensland, Australia.

Re: Dynamic Controls Power chair, RC Boat trailer project

Sold the Invacare M1 Roller 400aud.

For anyone with one that wont drive smooth, these are the settings i used, very smooth to drive now.

I have the same settings on the CAN bus Dynamic controller fitted to the Roller M1 AND the RS485 Dynamic Shark controller and the both drive very simlar but for the difference in Amperage of Power Module.

For anyone with one that wont drive smooth, these are the settings i used, very smooth to drive now.

I have the same settings on the CAN bus Dynamic controller fitted to the Roller M1 AND the RS485 Dynamic Shark controller and the both drive very simlar but for the difference in Amperage of Power Module.

http://greenmobility.com.au/rc-wheelchair-controller/

My YouTube Ch -- https://www.youtube.com/user/gcebiker

My YouTube Ch -- https://www.youtube.com/user/gcebiker

-

gcebiker - Posts: 879

- Joined: 11 Jul 2015, 14:20

- Location: Gold Coast, Queensland, Australia.

Re: Dynamic Controls Power chair, RC Boat trailer project

First run with prototype No.3 , needs some minor adjustments but overall i am very happy with it.

This version with the cowling on, fits under the boat trailer while its parked in the shed. Taking up less room while its not being used.

https://youtu.be/Ta24wr3IecQ

This version with the cowling on, fits under the boat trailer while its parked in the shed. Taking up less room while its not being used.

https://youtu.be/Ta24wr3IecQ

http://greenmobility.com.au/rc-wheelchair-controller/

My YouTube Ch -- https://www.youtube.com/user/gcebiker

My YouTube Ch -- https://www.youtube.com/user/gcebiker

-

gcebiker - Posts: 879

- Joined: 11 Jul 2015, 14:20

- Location: Gold Coast, Queensland, Australia.

Re: Dynamic Controls Power chair, RC Boat trailer project

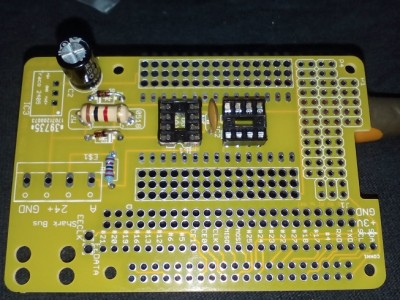

Dynamic Shark 50amp controller and the RC Arduino joystick i made.

http://greenmobility.com.au/rc-wheelchair-controller/

My YouTube Ch -- https://www.youtube.com/user/gcebiker

My YouTube Ch -- https://www.youtube.com/user/gcebiker

-

gcebiker - Posts: 879

- Joined: 11 Jul 2015, 14:20

- Location: Gold Coast, Queensland, Australia.

Re: Dynamic Controls Power chair, RC Boat trailer project

That power base in the above picture had a captains seat on it...

Took it off and stuck it on my indoor chair...OMG, so much better than every other cushion i have used.

Sprung steel seat like a recliner chair.

I was lucky and was able to just take the other cushion off the steel 'Tru Comfort Base with tilt'

Drill a few holes and bolt it straight on.

Its like driving around in a lounge chair

On an unrelated note...anyone know what to put on the shocks so they don't squeak ?

They have dried out over the winter, i a bit worried about putting any silicone spray on (i put it on every thing else) as it is quite runny and i don't want any thing making the tiles slippery for my wife.

Took it off and stuck it on my indoor chair...OMG, so much better than every other cushion i have used.

Sprung steel seat like a recliner chair.

I was lucky and was able to just take the other cushion off the steel 'Tru Comfort Base with tilt'

Drill a few holes and bolt it straight on.

Its like driving around in a lounge chair

On an unrelated note...anyone know what to put on the shocks so they don't squeak ?

They have dried out over the winter, i a bit worried about putting any silicone spray on (i put it on every thing else) as it is quite runny and i don't want any thing making the tiles slippery for my wife.

http://greenmobility.com.au/rc-wheelchair-controller/

My YouTube Ch -- https://www.youtube.com/user/gcebiker

My YouTube Ch -- https://www.youtube.com/user/gcebiker

-

gcebiker - Posts: 879

- Joined: 11 Jul 2015, 14:20

- Location: Gold Coast, Queensland, Australia.

Re: Dynamic Controls Power chair, RC Boat trailer project

Stuck a swivel seat on it, its one of the boat seats with the same quick release mounting.

This way i can face backwards when reversing, much more comfortable compared to twisting around.

Also increased the power up to its maximums of 60amps and 15amps boost, works well with myself sitting on the chair and pushing the boat around.

I did a few practice runs, reversing onto the street and back into the garage and it worked really really well.

With the turn run rate dialed down to 50% (via the pot on the RC controller) it was very controllable.

Forward speed is set to 100% and reverse to 70% via the Wizard software.

This way i can face backwards when reversing, much more comfortable compared to twisting around.

Also increased the power up to its maximums of 60amps and 15amps boost, works well with myself sitting on the chair and pushing the boat around.

I did a few practice runs, reversing onto the street and back into the garage and it worked really really well.

With the turn run rate dialed down to 50% (via the pot on the RC controller) it was very controllable.

Forward speed is set to 100% and reverse to 70% via the Wizard software.

http://greenmobility.com.au/rc-wheelchair-controller/

My YouTube Ch -- https://www.youtube.com/user/gcebiker

My YouTube Ch -- https://www.youtube.com/user/gcebiker

-

gcebiker - Posts: 879

- Joined: 11 Jul 2015, 14:20

- Location: Gold Coast, Queensland, Australia.

Re: Dynamic Controls Power chair, RC Boat trailer project

This started off as a project to add sensors to my chair so i would not run over my dog...well it took so long , ran over the dog, the dog learned and so it evolved into this.

Link to a bit of a demo/tear down of the RC wheelchair boat towing power chair.

https://www.youtube.com/watch?v=RP0mHbw7hyU

The board is still capable of having more inputs/outputs added.

This reuses the stock wheelchair controller to cheaply build a wheelchair that is able to do more beyond its normal lifespan.

Next steps,

Change the wiring over to the DX Shark Bus cables so its all hot swap-able between chairs.

Make better boards or work with someone to do it... /beg anyone ?

Rebox

Expand upon the features in the current one as needed, such as tilt/lights/horn.

Link to a bit of a demo/tear down of the RC wheelchair boat towing power chair.

https://www.youtube.com/watch?v=RP0mHbw7hyU

The board is still capable of having more inputs/outputs added.

This reuses the stock wheelchair controller to cheaply build a wheelchair that is able to do more beyond its normal lifespan.

Next steps,

Change the wiring over to the DX Shark Bus cables so its all hot swap-able between chairs.

Make better boards or work with someone to do it... /beg anyone ?

Rebox

Expand upon the features in the current one as needed, such as tilt/lights/horn.

http://greenmobility.com.au/rc-wheelchair-controller/

My YouTube Ch -- https://www.youtube.com/user/gcebiker

My YouTube Ch -- https://www.youtube.com/user/gcebiker

-

gcebiker - Posts: 879

- Joined: 11 Jul 2015, 14:20

- Location: Gold Coast, Queensland, Australia.

Re: Dynamic Controls Power chair, RC Boat trailer project

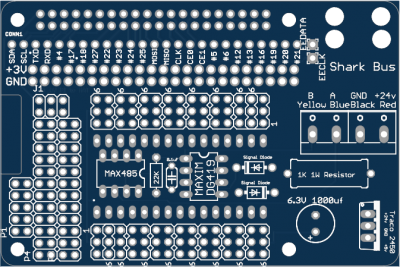

Radio Control - Arduino Shark Bus Emulator for the Dynamic Shark Power Wheelchair Controller

Just in case you have not been following the other thread, Sir Mike from Canada was able to get me started with Eagle CAD and we now have Two Versions available.

From the other thread...

Blue boards work great...once i put the jumper in.

I have 18 spare boards, 9 of the Yellow and 9 of the Blue.

Anyone in Australia Wanting one, partially populated (resistors, IC sockets), i wont be able to post with the caps soldered in but will include them in the parcel.

$25 delivered with signature - Australia Only

Yellow have the larger holes on the input / output sides of the Arduino, larger holes for power resistor.

Blue is better laid out, corrected hole sizes, i will put the wire link in as well as the other minor components for anyone wanting one.

I have enough components to fully build up and test 5 Blue Boards if anyone wants a completed version, you will have to supply your own RC unit and wiring.

P.O.A

Posting to Overseas....OMG, From Australia...postage its expensive, on the upside, our Dollar is rubbish...so its like 75% off , prices i have listed are in AUD.

Probably still cheaper to just order 10 from DirtyPCB

Next version (not available as yet, till testing can be done on the Raspberry Pi Sections SirMike is interested in/requested)

Ver 3.25 has the power to the Arduino fixed, a link/place for putting a switch should you want to leave it connected but turned off.

Amendments to the code would also enable this to remain connected and able to remotely turn the Radio Control Sections On/Off the same as Woodys JC2000 Joystick RC Arduino Bluetooth Smart Phone Version is able to do for the VSI style joysticks or if you prefer the WJJRCABS, maybe one of you military types might be able to come up with a harder to remember acronym ?

My YouTube Channel is 'gcebiker' a few videos there of this build process, first the Wii Remote Control for the Power Chair i built

In later videos i am using it with a PPM 2.4Ghz RC Transmitter from Hobby King to move my boat out the street so i can connect it to the car.

There is a seat on the Power chair / Boat tower so that it can carry me and the boat.

The Seat is on a swivel so i can watch where i am going with out having to twist around. The same seat then comes off and can go into the boat for use.

Just in case you have not been following the other thread, Sir Mike from Canada was able to get me started with Eagle CAD and we now have Two Versions available.

From the other thread...

Blue boards work great...once i put the jumper in.

I have 18 spare boards, 9 of the Yellow and 9 of the Blue.

Anyone in Australia Wanting one, partially populated (resistors, IC sockets), i wont be able to post with the caps soldered in but will include them in the parcel.

$25 delivered with signature - Australia Only

Yellow have the larger holes on the input / output sides of the Arduino, larger holes for power resistor.

Blue is better laid out, corrected hole sizes, i will put the wire link in as well as the other minor components for anyone wanting one.

I have enough components to fully build up and test 5 Blue Boards if anyone wants a completed version, you will have to supply your own RC unit and wiring.

P.O.A

Posting to Overseas....OMG, From Australia...postage its expensive, on the upside, our Dollar is rubbish...so its like 75% off , prices i have listed are in AUD.

Probably still cheaper to just order 10 from DirtyPCB

Next version (not available as yet, till testing can be done on the Raspberry Pi Sections SirMike is interested in/requested)

Ver 3.25 has the power to the Arduino fixed, a link/place for putting a switch should you want to leave it connected but turned off.

Amendments to the code would also enable this to remain connected and able to remotely turn the Radio Control Sections On/Off the same as Woodys JC2000 Joystick RC Arduino Bluetooth Smart Phone Version is able to do for the VSI style joysticks or if you prefer the WJJRCABS, maybe one of you military types might be able to come up with a harder to remember acronym ?

My YouTube Channel is 'gcebiker' a few videos there of this build process, first the Wii Remote Control for the Power Chair i built

In later videos i am using it with a PPM 2.4Ghz RC Transmitter from Hobby King to move my boat out the street so i can connect it to the car.

There is a seat on the Power chair / Boat tower so that it can carry me and the boat.

The Seat is on a swivel so i can watch where i am going with out having to twist around. The same seat then comes off and can go into the boat for use.

http://greenmobility.com.au/rc-wheelchair-controller/

My YouTube Ch -- https://www.youtube.com/user/gcebiker

My YouTube Ch -- https://www.youtube.com/user/gcebiker

-

gcebiker - Posts: 879

- Joined: 11 Jul 2015, 14:20

- Location: Gold Coast, Queensland, Australia.

Re: Dynamic Controls Power chair, RC Boat trailer project

Squid season back again...figured i best put the Shark joystick EMU in a box properly.

Some pictures of the assembly today.

Factory Shark Bus cable used

Blue jumper on the lower of this picture is for supply of 5v to the Arduino Nano V3.0

A switch may be wired into here for turning off the EMU while not in use.

Some pictures of the assembly today.

Factory Shark Bus cable used

Blue jumper on the lower of this picture is for supply of 5v to the Arduino Nano V3.0

A switch may be wired into here for turning off the EMU while not in use.

http://greenmobility.com.au/rc-wheelchair-controller/

My YouTube Ch -- https://www.youtube.com/user/gcebiker

My YouTube Ch -- https://www.youtube.com/user/gcebiker

-

gcebiker - Posts: 879

- Joined: 11 Jul 2015, 14:20

- Location: Gold Coast, Queensland, Australia.

Re: Dynamic Controls Power chair, RC Boat trailer project

PolyCraft Tough Tender / Gal trailer/ Yamaha 6hp 4 stroke motor just slightly too heavy for a round trip to the ramp and back.

... trying again with a Hobie Pro Angler 14 - Sail kit and Electric motor.

... trying again with a Hobie Pro Angler 14 - Sail kit and Electric motor.

http://greenmobility.com.au/rc-wheelchair-controller/

My YouTube Ch -- https://www.youtube.com/user/gcebiker

My YouTube Ch -- https://www.youtube.com/user/gcebiker

-

gcebiker - Posts: 879

- Joined: 11 Jul 2015, 14:20

- Location: Gold Coast, Queensland, Australia.

Re: Dynamic Controls Power chair, RC Boat trailer project

gcebiker wrote:Next version (not available as yet, till testing can be done on the Raspberry Pi Sections SirMike is interested in/requested)

Ver 3.25 has the power to the Arduino fixed, a link/place for putting a switch should you want to leave it connected but turned off.

A few constructive criticisms re: layout (none are deal-breakers):

- pick a single orientation for your components (even if it makes the layout a bit harder). I.e., all chips facing the same way, pin 1's always pointed the same way, '+' terminals of polarized components (caps, diodes) facing the same direction

- consider using a square pad to make "pin 1" (or '+', etc.) more readily identifiable

- consider adding reference designators (instead of component part numbers) to the silkscreen. How would you reference the "top diode" if trying to describe something to someone else ("While holding the board with the power connector on the right-hand side, component side exposed, the diode closest to the top edge of the board...")

- add one (or more) tie-points for "ground" to make connecting a 'scope probe (or DMM "common" lead) easier. You can stuff a stiff piece of wire into the pad to make it easier to clip onto during testing

- leave a larger "keep out" zone around mounting holes. Imagine putting metal (conductive) fasteners in/under those holes and wondering if you'll have to ADD an insulating (nylon) washer to prevent unintended shorts

- consider surrounding (one or more) mounting holes with "ground" if you want to be able to electrically tie the board's ground to your chassis/enclosure

- try to run stubs off to individual pads instead of routing a trace "across" a pad (i.e., imagine how you would isolate the - conductor of the eCap from the "ground" signal that runs through that pad vs. how you'd isolate pin 5 of the MAX485 from that same signal

- leave as much space as possible for mounting components (e.g., that resistor near the MAX485 could probably benefit from a wider separation between mounting holes -- unless you want to mount it "on end" <frown>); ditto the two diodes

- traces on the underside of the board are usually easier to follow while troubleshooting a circuit ("Where else does this signal go?")

Keep in mind that the silkscreen is only visible from one side of the board (you can pay for screens on both sides -- or, NONE!). So, when you're soldering -- or PROBING! -- components from the underside of the board, you have to make a special effort to keep track of which specific pin you're looking for (a "convention" makes it easier to avoid mistakes -- esp when you're frustrated trying to trace down a problem). And, if the installed component COVERS the silkscreen legend for that component, its hard to verify that the component is installed properly and sort out which lead is which.

[I have no idea of the purpose for the large "heavily perforated" area to the left side of the board; perhaps a "breadboarding" area?]

- Scout

- Posts: 71

- Joined: 23 Nov 2017, 21:29

- Location: USA

Re: Dynamic Controls Power chair, RC Boat trailer project

Again, some comments on "style":

Numeric constants are A Bad Idea in almost all cases. They force the reader (who may not be you -- or, who may be you 6 months from now!) to wonder what they mean and where they came from. And, as most folks are lazy in terms of chasing down API details and RE-verifying the proper values for any particular instance of a function invocation, it is likely that you (or "he") will convince yourself of what you THINK a parameter means and gloss over an error that would otherwise be more visible.

E.g., (my guesstimates as to what your code is doing, based on what I think it SHOULD be doing):

I'd question why the need to "constrain" these values. What could cause an "invalid" value (needing to be constrained)? Wouldn't that also be indicative of Something Wrong, somewhere? If that's the case, then you really want to be trapping those conditions and doing something about them (like signalling an error). If they "can't happen", but DO happen, then you're reasoning is either defective OR something unexpected has happened! AND, you probably want to know about either of these cases!

I've no idea whether these functions are part of a support library or things you crafted, yourself. But, with that many parameters, it gets hard to remember what order they are expected in the argument list. For example, these are all potentially valid prototypes for a "map" function:

This is particularly important when more than one author is involved in a codebase (e.g., one library author may have a different set of conventions than the author of another library -- and both may have a different set of conventions than the primary application author(s)!)

gcebiker wrote:

- Code: Select all

{

directionPotVal = analogRead(directionPot);

directionPotVal = constrain(directionPotVal, 1, 1023);// Constrain to real numbers. 0 and 1024 are out of range for the controller.

direction = map(directionPotVal, 0, 1024, 1, 1023); //here in case direction is inverted in wiring

if (direction > 312 && direction < 712) // set dead zone of joystick

direction = 512;

}

{

speedPotVal = analogRead(speedPot);

speedPotVal = constrain(speedPotVal, 1, 1023); // Constrain value to real numbers.

speed = map(speedPotVal, 0, 1024, 1023, 1 ); // here in case of speed is inverted in wiring

//speed dead zone mapping

if (speed > 312 && speed < 712) // set dead zone of joystick

speed = 512;

}

Numeric constants are A Bad Idea in almost all cases. They force the reader (who may not be you -- or, who may be you 6 months from now!) to wonder what they mean and where they came from. And, as most folks are lazy in terms of chasing down API details and RE-verifying the proper values for any particular instance of a function invocation, it is likely that you (or "he") will convince yourself of what you THINK a parameter means and gloss over an error that would otherwise be more visible.

E.g., (my guesstimates as to what your code is doing, based on what I think it SHOULD be doing):

- Code: Select all

{

directionPotVal = analogRead(directionPot);

#define MIN_DIRECTION_POT (1) // '0' is out of controller's range

#define MAX_DIRECTION_POT (1023) // '1024' is out of controller's range

directionPotVal = constrain(directionPotVal, MIN_DIRECTION_POT, MAX_DIRECTION_POT);// Constrain to valid numbers. Others are out of range for the controller.

#define MIN_DIRECTION (0) // minimum value of "direction" variable

#define MAX_DIRECTION (1024) // maximum value of "direction" variable

direction = map(directionPotVal, MIN_DIRECTION, MAX_DIRECTION, MIN_DIRECTION_POT, MAX_DIRECTION_POT); //here in case direction is inverted in wiring

#define DIRECTION_CENTERED ((MAX_DIRECTION - MIN_DIRECTION)/2)

#define DIRECTION_DEADBAND (400) // width of deadband in "direction" units

#define DIRECTION_LOW_DEADBAND (DIRECTION_CENTERED - DIRECTION_DEADBAND/2)

#define DIRECTION_HIGH_DEADBAND (DIRECTION_CENTERED + DIRECTION_DEADBAND/2)

if ( (direction > DIRECTION_LOW_DEADBAND)

&& (direction < DIRECTION_HIGH_DEADBAND) )

direction = DIRECTION_CENTERED; // treat direction as "centered" if within deadband

}

[...]

I'd question why the need to "constrain" these values. What could cause an "invalid" value (needing to be constrained)? Wouldn't that also be indicative of Something Wrong, somewhere? If that's the case, then you really want to be trapping those conditions and doing something about them (like signalling an error). If they "can't happen", but DO happen, then you're reasoning is either defective OR something unexpected has happened! AND, you probably want to know about either of these cases!

I've no idea whether these functions are part of a support library or things you crafted, yourself. But, with that many parameters, it gets hard to remember what order they are expected in the argument list. For example, these are all potentially valid prototypes for a "map" function:

- Code: Select all

map(value, minimum_range, maximum_range, minimum_domain, maximum_domain);

map(value, minimum_domain, maximum_domain, minimum_range, maximum_range);

map(value, minimum_range, minimum_domain, maximum_range, maximum_domain);

map(value, maximum_range, minimum_range, maximum_domain, minimum_domain);

[...]

This is particularly important when more than one author is involved in a codebase (e.g., one library author may have a different set of conventions than the author of another library -- and both may have a different set of conventions than the primary application author(s)!)

- Scout

- Posts: 71

- Joined: 23 Nov 2017, 21:29

- Location: USA

Re: Dynamic Controls Power chair, RC Boat trailer project

I think that Scout's comments are well taken, but would be cautious about one suggestion:

IF the chassis/enclosure is not isolated from the chair framework, you have now created a low-impedance connection between ground and the chair frame. If ground is also B-, that is a direct connection of the battery negative to the frame. That is an absolute NO NO for wheelchairs - unlike a car where the driver can usually run away if there's a fire, a WC user usually cannot.

I would also consider going to an SMD version. I was leery of doing that, but discovered that SMD is actually easier and faster to do than through hole, and it doesn't really take any expensive equipment for small runs. I use: (1) an ordinary toaster-oven and watch with sweep second hand, (2) very fine solder that I flatten and cut into pieces that I stick to the board with good (sticky) flux, and (3) a stereo microscope and fine tweezers for manual pick and place. A good, large magnifying glass or magnifier headset would do as well, but I already had the scope. Placing the components is the trickiest part for my old hands, but once that's done the whole board is reflow soldered in a matter of minutes. Sure, if I had a lot to do a pick-and-place robot, a real reflow oven, stencils and fresh solder paste would make it even easier, but for a few small to medium sized boards at a time, my crude setup works pretty well - once in a while I have to fix a component that "gravestones" during reflow, but I've only once had a solder bridge and only once had a cold joint. I've fu'ed point-to-point wiring a lot more often.

consider surrounding (one or more) mounting holes with "ground" if you want to be able to electrically tie the board's ground to your chassis/enclosure

IF the chassis/enclosure is not isolated from the chair framework, you have now created a low-impedance connection between ground and the chair frame. If ground is also B-, that is a direct connection of the battery negative to the frame. That is an absolute NO NO for wheelchairs - unlike a car where the driver can usually run away if there's a fire, a WC user usually cannot.

I would also consider going to an SMD version. I was leery of doing that, but discovered that SMD is actually easier and faster to do than through hole, and it doesn't really take any expensive equipment for small runs. I use: (1) an ordinary toaster-oven and watch with sweep second hand, (2) very fine solder that I flatten and cut into pieces that I stick to the board with good (sticky) flux, and (3) a stereo microscope and fine tweezers for manual pick and place. A good, large magnifying glass or magnifier headset would do as well, but I already had the scope. Placing the components is the trickiest part for my old hands, but once that's done the whole board is reflow soldered in a matter of minutes. Sure, if I had a lot to do a pick-and-place robot, a real reflow oven, stencils and fresh solder paste would make it even easier, but for a few small to medium sized boards at a time, my crude setup works pretty well - once in a while I have to fix a component that "gravestones" during reflow, but I've only once had a solder bridge and only once had a cold joint. I've fu'ed point-to-point wiring a lot more often.

- LROBBINS

- Posts: 5789

- Joined: 27 Aug 2010, 09:36

- Location: Siena, Italy

Re: Dynamic Controls Power chair, RC Boat trailer project

Its all mirrored from the Dynamic Controls wiring,

I have already said...this is my first Arduino code, others are welcome to mod it.

Its been posted publicly for just this reason.

Also my first board, please do build on the work i have done to improve it.

This is iteration 3.25

This is Ver 3.23

It will benefit the whole community.

In real world application i found i needed to make code tweaks, videos on YouTube 'gcebiker' , May clear it up.

As it is presently is, its working very very well but the load on the chair (pulling a boat and myself up a boat ramp) is not possible with the current power base and current limitations i am working with.

Thus i have reduced the load i am asking the chair to pull and moved to a Hobie Kayak for this Squid season.

I may make a smaller version that is not Pi compatible but have not bothered as yet as this board is able to be cut up if needed.

Scout,

Please make the code alterations as you see fit and upload, i will be happy to test it on the EMU if you don't have one built up.

Cheers

Tony

I have already said...this is my first Arduino code, others are welcome to mod it.

Its been posted publicly for just this reason.

Also my first board, please do build on the work i have done to improve it.

This is iteration 3.25

This is Ver 3.23

It will benefit the whole community.

In real world application i found i needed to make code tweaks, videos on YouTube 'gcebiker' , May clear it up.

As it is presently is, its working very very well but the load on the chair (pulling a boat and myself up a boat ramp) is not possible with the current power base and current limitations i am working with.

Thus i have reduced the load i am asking the chair to pull and moved to a Hobie Kayak for this Squid season.

I may make a smaller version that is not Pi compatible but have not bothered as yet as this board is able to be cut up if needed.

Scout,

Please make the code alterations as you see fit and upload, i will be happy to test it on the EMU if you don't have one built up.

Cheers

Tony

http://greenmobility.com.au/rc-wheelchair-controller/

My YouTube Ch -- https://www.youtube.com/user/gcebiker

My YouTube Ch -- https://www.youtube.com/user/gcebiker

-

gcebiker - Posts: 879

- Joined: 11 Jul 2015, 14:20

- Location: Gold Coast, Queensland, Australia.

Re: Dynamic Controls Power chair, RC Boat trailer project

Scout wrote:gcebiker wrote:Next version (not available as yet, till testing can be done on the Raspberry Pi Sections SirMike is interested in/requested)

Ver 3.25 has the power to the Arduino fixed, a link/place for putting a switch should you want to leave it connected but turned off.

A few constructive criticisms re: layout (none are deal-breakers):

- pick a single orientation for your components (even if it makes the layout a bit harder). I.e., all chips facing the same way, pin 1's always pointed the same way, '+' terminals of polarized components (caps, diodes) facing the same direction

- consider using a square pad to make "pin 1" (or '+', etc.) more readily identifiable

- consider adding reference designators (instead of component part numbers) to the silkscreen. How would you reference the "top diode" if trying to describe something to someone else ("While holding the board with the power connector on the right-hand side, component side exposed, the diode closest to the top edge of the board...")

- add one (or more) tie-points for "ground" to make connecting a 'scope probe (or DMM "common" lead) easier. You can stuff a stiff piece of wire into the pad to make it easier to clip onto during testing

- leave a larger "keep out" zone around mounting holes. Imagine putting metal (conductive) fasteners in/under those holes and wondering if you'll have to ADD an insulating (nylon) washer to prevent unintended shorts

- consider surrounding (one or more) mounting holes with "ground" if you want to be able to electrically tie the board's ground to your chassis/enclosure

- try to run stubs off to individual pads instead of routing a trace "across" a pad (i.e., imagine how you would isolate the - conductor of the eCap from the "ground" signal that runs through that pad vs. how you'd isolate pin 5 of the MAX485 from that same signal

- leave as much space as possible for mounting components (e.g., that resistor near the MAX485 could probably benefit from a wider separation between mounting holes -- unless you want to mount it "on end" <frown>); ditto the two diodes

- traces on the underside of the board are usually easier to follow while troubleshooting a circuit ("Where else does this signal go?")

Keep in mind that the silkscreen is only visible from one side of the board (you can pay for screens on both sides -- or, NONE!). So, when you're soldering -- or PROBING! -- components from the underside of the board, you have to make a special effort to keep track of which specific pin you're looking for (a "convention" makes it easier to avoid mistakes -- esp when you're frustrated trying to trace down a problem). And, if the installed component COVERS the silkscreen legend for that component, its hard to verify that the component is installed properly and sort out which lead is which.

[I have no idea of the purpose for the large "heavily perforated" area to the left side of the board; perhaps a "breadboarding" area?]

Its not a commercial board...

The rest of it is for a Pi Hat, someone else designed...I have no idea about Pi's or their Hat's

Please do redesign it in Eagle and share the board,

As you say best practice is many things i have not done with my first attempt at this.

I look forward to your contributions.

Cheers

Tony

http://greenmobility.com.au/rc-wheelchair-controller/

My YouTube Ch -- https://www.youtube.com/user/gcebiker

My YouTube Ch -- https://www.youtube.com/user/gcebiker

-

gcebiker - Posts: 879

- Joined: 11 Jul 2015, 14:20

- Location: Gold Coast, Queensland, Australia.

Re: Dynamic Controls Power chair, RC Boat trailer project

gcebiker wrote:Next version...

Its not a commercial board...

The rest of it is for a Pi Hat, someone else designed...I have no idea about Pi's or their Hat's

Understandable. I only offered my comments as "tips" for your own personal edification (ooo! now THAT's a big word!

)

)Please do redesign it in Eagle and share the board,

Sorry, but I don't use Eagle (I use OrCAD/Cadence and Protel/Altium).

- Scout

- Posts: 71

- Joined: 23 Nov 2017, 21:29

- Location: USA

Re: Dynamic Controls Power chair, RC Boat trailer project

LROBBINS wrote:I think that Scout's comments are well taken, but would be cautious about one suggestion:consider surrounding (one or more) mounting holes with "ground" if you want to be able to electrically tie the board's ground to your chassis/enclosure

IF the chassis/enclosure is not isolated from the chair framework, you have now created a low-impedance connection between ground and the chair frame. If ground is also B-, that is a direct connection of the battery negative to the frame. That is an absolute NO NO for wheelchairs - unlike a car where the driver can usually run away if there's a fire, a WC user usually cannot.

The advantage to grounding the enclosure is that it helps cut down on radiated noise. If you're a manufacturer, you can afford to have PLASTIC enclosures that are coated with conductive paint on the inside.

I would also consider going to an SMD version. I was leery of doing that, but discovered that SMD is actually easier and faster to do than through hole, and it doesn't really take any expensive equipment for small runs. I use: (1) an ordinary toaster-oven and watch with sweep second hand, (2) very fine solder that I flatten and cut into pieces that I stick to the board with good (sticky) flux, and (3) a stereo microscope and fine tweezers for manual pick and place. A good, large magnifying glass or magnifier headset would do as well, but I already had the scope. Placing the components is the trickiest part for my old hands, but once that's done the whole board is reflow soldered in a matter of minutes. Sure, if I had a lot to do a pick-and-place robot, a real reflow oven, stencils and fresh solder paste would make it even easier, but for a few small to medium sized boards at a time, my crude setup works pretty well - once in a while I have to fix a component that "gravestones" during reflow, but I've only once had a solder bridge and only once had a cold joint. I've fu'ed point-to-point wiring a lot more often.

I would recommend AGAINST doing it -- esp for a hobbyist market. Few people can really do SMT work reliably -- esp if they are doing "one off". When I assemble SMT prototypes, I prefer to do component-at-a-time with a Leister (

-- they don't sell my 30 year old unit anymore but this gives a rough idea; blower is in a separate box on the other end of that black hose). It's just too hard to get ALL the components in place (without adhesive) and then bake the complete board. By soldering one at a time, I don't have to worry about accidentally bumping a previously placed component and knocking it out of position.

-- they don't sell my 30 year old unit anymore but this gives a rough idea; blower is in a separate box on the other end of that black hose). It's just too hard to get ALL the components in place (without adhesive) and then bake the complete board. By soldering one at a time, I don't have to worry about accidentally bumping a previously placed component and knocking it out of position.I use solder paste (comes in a 10cc syringe) with a manual "paste gun" ("DispensGun" -- also, too old to still be offered for sale) and choose a "needle" (nozzle?) of appropriate diameter to the bead of solder I want to lay down. More labor intensive than a stencil but saves me the trouble of having stencils cut!

To see what I'm doing, I use a "Flipperport" autofocus camera with LCD goggles

or an old B&L stereoscope

or an old B&L stereoscope on a long mounting arm (though mine is black). The Flipperport is nice as I can keep my face away from any fumes coming off the board -- I can even look in a different direction as the goggles are wed to my eyes! Not possible with the stereomicroscope that must hover above the work.

on a long mounting arm (though mine is black). The Flipperport is nice as I can keep my face away from any fumes coming off the board -- I can even look in a different direction as the goggles are wed to my eyes! Not possible with the stereomicroscope that must hover above the work.The other problem with SMT is servicing/repairing an existing board that develops a fault, down the road. Chances are, you laid out the board "tight" (or, at least, tighter than you would have with thru-hole) and now you've got to work in those cramped quarters to try to remove a component without screwing up any of the surrounding bits of kit.

Given that Tony's board is largely defined by the MCU module and the attendant connectors/connections, I don't think he's going to save much by going to an SMT fab. If I have to make more than one of an item, I'll just hire it out to someone (or, "tap" a friend in the business) who can knock it off in no time. By contrast, I have no problem building small lots of thru-hole designs -- it's almost therapeutic to stuff the boards, flip them over and then touch all the pads with some solder!

- Scout

- Posts: 71

- Joined: 23 Nov 2017, 21:29

- Location: USA

Return to Everything Powerchair